A new generation of wine yeasts that helps to manage undesirable sulfur compounds in wines

Publiée le 18/02/2020 12:25In a collaborative study conducted with the ICV Group, Montpellier Supagro and the INRA Montpellier (through a PhD focusing on the genetic basis of sulfur production by yeast to identify the molecular determinants involved in the yeast’s SO₂ metabolism, carried out in 2011 by Jessica Noble with Bruno Blondin, from the INRA Montpellier as PhD supervisor), Lallemand Oenology identified, through an innovative QTL approach, the molecular basis of SO₂ production in yeast to eventually be able to reduce SO₂ production.

Context

Consumer awareness of SO₂ content in wine, particularly since the label “Contains sulphites” is mandatory, has resulted in a trend toward reducing the addition rate of this compound. Reducing SO₂ content, both added and total residual dose, is now a serious technical and commercial issue for wine producers. Formation of compounds such as acetaldehyde (SO₂-binding) and H₂S (wine fault, rotten-egg aroma) are also a worrisome concern during winemaking.

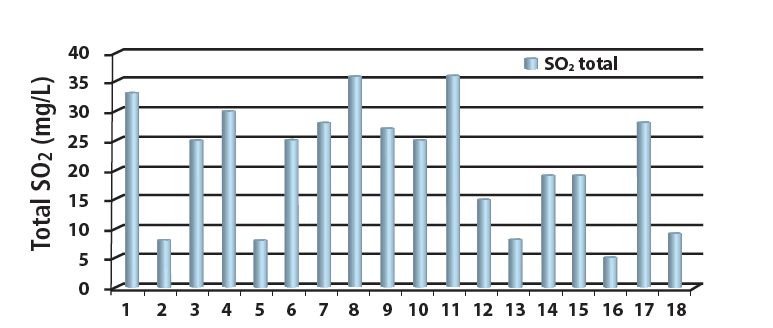

Wine yeast are at the heart of the SO₂, acetaldehyde and H₂S production as they can be synthesized during fermentation. However, there is great variability in SO₂ produced by wine yeast during fermentation.

In a collaborative study conducted with the ICV Group, Montpellier Supagro and the INRA Montpellier (through a PhD focusing on the genetic basis of sulfur production by yeast to identify the molecular determinants involved in the yeast’s SO₂ metabolism, carried out in 2011 by Jessica Noble with Bruno Blondin, from the INRA Montpellier as PhD supervisor), Lallemand Oenology identified, through an innovative QTL approach, the molecular basis of SO₂ production in yeast to eventually be able to reduce SO₂ production.

What is QTL?

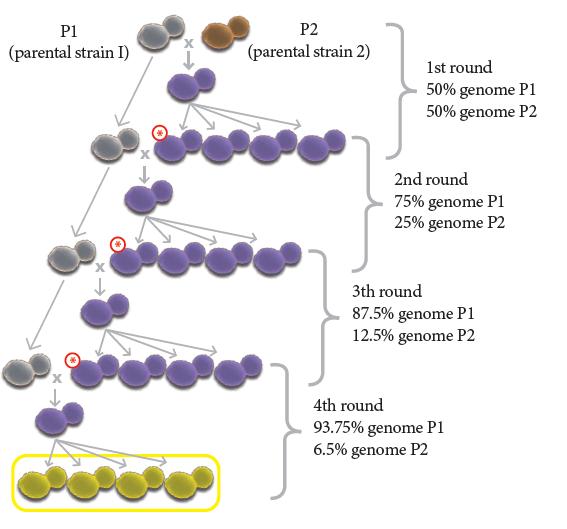

The QTL process involves identifying the genes for the desired trait (for instance non-production of SO₂, acetaldehyde and H₂S) and use this knowledge to select another yeast combining those desired traits and other interesting oenological properties. This selection method involves repeated crosses (backcrossing) between the low-SO₂ yeast and the target yeast.

The first part of the collaborative study identified the metabolic pathways and, above all, the genetic basis of yeast SO₂, H₂S, and acetaldehyde production. This method involved first crossing two wine yeasts with very contrasting enological characteristics: one producing low levels of SO₂ and the other with high SO₂ production.

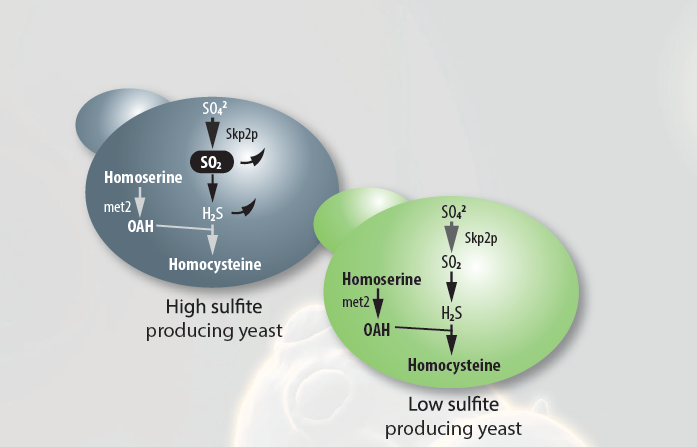

This first cross resulted in a population of ‘daughter’ yeast with a high diversity and very variable properties due to huge possibilities of recombination. Each yeast was then subjected to genotypic (genome mapping to identify the parental origin) and phenotypic (actual quantity of SO₂ produced) analysis. Reconciling this data, we identified two genome regions (called QTL – Quantitative Trait Loci) directly involved in SO₂, H₂S, and acetaldehyde production. It was therefore proved that these genome regions were involved in controlling the sulfate assimilation pathway.

The second stage involved naturally conferring these interesting characteristics identified (very low SO₂, H₂S and acetaldehyde production) into a target wine yeast, chosen for its fermentation capacity and enological interest. This target wine yeast was simply crossed once with the low SO₂, H₂S and acetaldehyde producing yeast, and then several times with ‘daughter’ yeasts possessing interesting characteristics. This gave a more precise cross (93.75 % of the target yeast’s genome preserved).

This is a non-GMO technique that can occur naturally in yeast.

This work resulted in a patent application ((PTC/IB220131050623), filed by INRA and Montpellier SupAgro: «Method of control on the production of sulfites, hydrogen sulfur and acetaldehyde by yeast (Variants MET₂ / SKP₂)”. With this method, we obtain yeasts producing very low to no concentrations of SO₂, H₂S and acetaldehyde. Lowering the production of negative S-related compounds by the QTL wine yeast to below the sensory threshold allows the aromatic fruit contribution to be expressed in the wine.

Conclusions

Since we found out this groundbreaking new selection and patented technique we have been able to obtain various wine yeasts producing very low to no concentrations of SO₂, H₂S and acetaldehyde and adapted to the production of very aromatic rosé, white and red wines, among which:

· Lalvin ICV Okay™ was the first yeast obtained with this method in 2013. It received a Citation Award in the category of Innovation from SITEVI 2013. The yeast combines reliable fermentation performance and very low production of SO₂, H₂S and acetaldehyde. It is particularly recommended for aromatic white and rosé wines, ensuring low levels of volatile acidity, promoting aromatic esters and bringing freshness and balance in the mouth.

· Lalvin Sensy™ will produce no or very little H₂S which is a great advantage to express varietal aroma from white grape varieties. The low acetaldehyde production by Lalvin Sensy™ will be a good asset to stabilize wines through moderate SO₂ use. Lalvin Sensy™ combines all the assets of a yeast needed to conduct fermentation in white varieties. It also produces a moderate level of fermentative aromas, respecting the varietal aromas of the grape variety

· Lalvin ICV Opale 2.0™ is a yeast for white and rosé wines, and cider to bring out exotic and citrus aromas, while maintaining freshness. Lalvin ICV Opale 2.0™ exhibits a special ability to produce very low level of H₂S and SO₂. Moreover, the final level of acetaldehyde fermented with ICV Opale 2.0™ will be a good asset to stabilize most wines with moderate SO₂ level.

· And Lalvin Persy™, which is the very last yeast obtained with the QTL selection method. This yeast is intended for red grape varieties, such as Shiraz, Pinot noir, Merlot or Tempranillo, which have a certain trend to express sulfur off flavors and reduction characteristics. These characteristics mask the red fruit aromas and thus have a negative impact on wine. Thanks to its unique properties, such as the non-production of SO₂ and non-perceptible levels of H₂S, Lalvin Persy™ is the right choice to ferment red varietals like Shiraz, Tempranillo or Pinot noir, enhancing bright red fruit character, freshness and aroma persistency.

Looking into the future

We will continue to apply this QTL innovative approach to other wine yeasts as it offers opportunities to bring out the best characteristics of naturally selected yeast. Lallemand Oenology will pursue its R&D efforts to continue offering winemakers solutions answering the challenges they are confronted with.

FAQ

- Are these yeasts GMO yeast?

No. These yeasts are hybrid yeast that can exists naturally. They are not GMO.

- Do I risk having less stable wines after using one of these yeasts?

The SO₂ produced by yeast is normally bound, so there is no impact on the stability of the wines. The low acetaldehyde production is at the contrary beneficial for wine stability, encouraging more efficient SO₂ addition thanks to less binding.

- Do these yeasts consume SO₂ during alcoholic fermentation?

SO₂ is usually consumed by Saccharomyces yeast through the sulphate pathway metabolism. The specific metabolism of these yeasts utilizes SO₂ directly to synthesize two essential amino acids containing sulphur, thus avoiding the release of H₂S.

- Can these yeasts dominate wild yeasts when no sulphite is added to the must?

These yeasts show strong fermentative properties. Their quick onset of fermentation and good multiplication during the growth phase discourage the development of indigenous flora.

- Due to their low SO₂ production, do these yeasts favor malolactic fermentation?

They do favor MLF. In the case of wines where MLF is not wanted, the winemaker should closely monitor the final phase of alcoholic fermentation and apply good SO₂ practices to avoid MLF.