News and Innovation in wine bacteria : the MBR process

Publiée le 13/02/2018 17:20Selected wine bacteria must be efficient as soon as they enter the must or wine to complete malolactic fermentation. It means that they must survive and grow in the must or wines to rapidly convert malic acid into lactic acid, as well as contribute to the wine sensory profile. In order to achieve this goal and based on our strong expertise in bacteria production, we developed a specific bacteria production process called « MBR™ process ».

WINE BACTERIA : HIGH PERFORMANCE MBR™ PROCESS

The MBR™ process developped from our research on the physiological and biochemical answers to stress by MLB, provides robust and efficient adapted wine bacteria, to inoculate directly into the tank without rehydration, with a good MLF performance.

Of our 8 production plants for bacteria, the one in France is solely dedicated to the wine bacteria. Each of our 30 different Oenococcus oeni or Lactobacillus plantarum selected for wine, has a specific production protocol that has been optimized for their best efficacy.

MBR™ PROCESS VERSUS LIQUID CULTURE

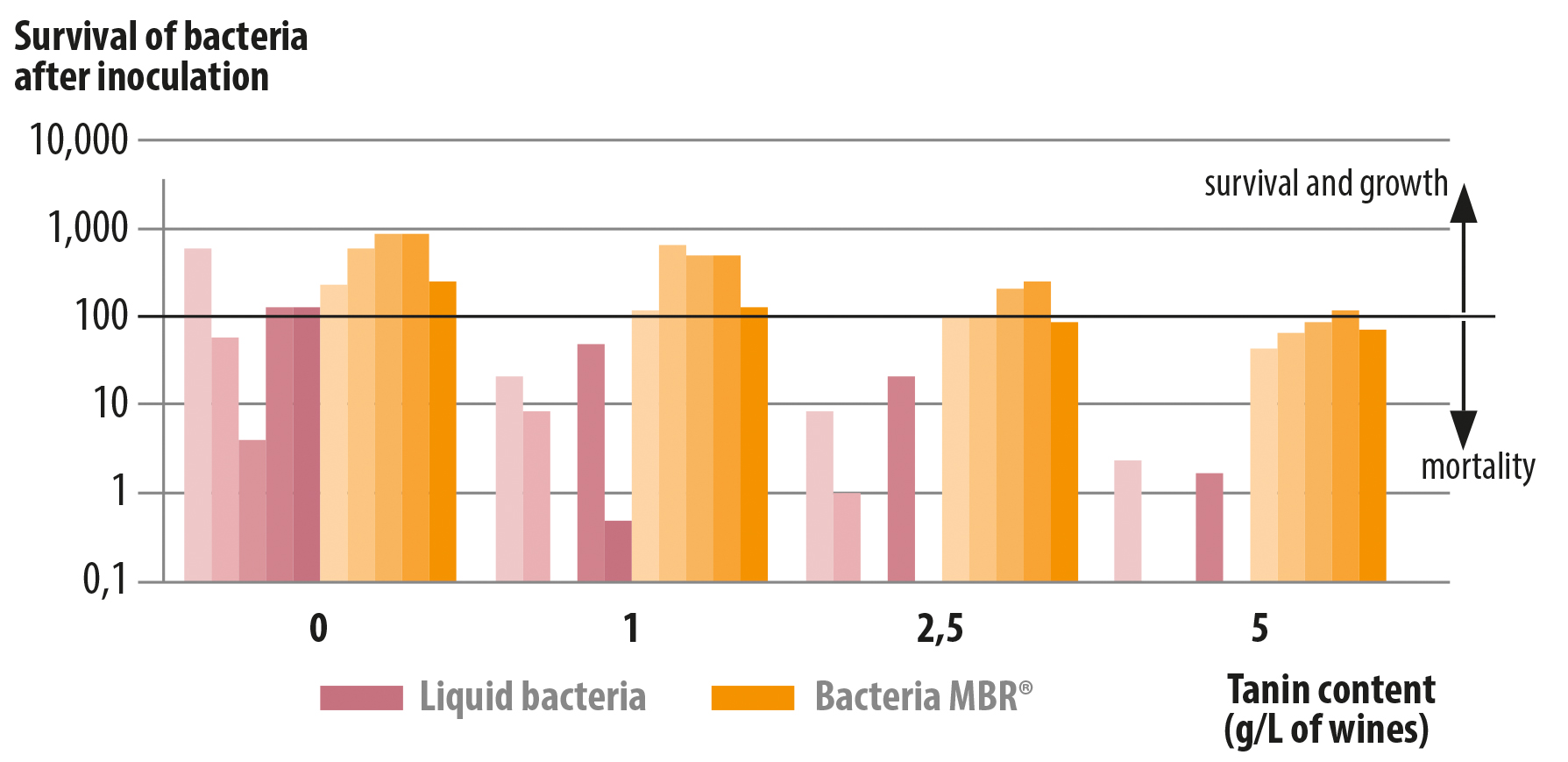

Studies have shown (Ph.D Thesis 2017 Marion Breniaux, University of Bordeaux) that how wine bacteria cultures are prepared is crucial on how they react to different conditions. For example, a recent study done at the University of Bordeaux showed that once wine bacteria are taken outside of the wine environment to a liquid laboratory medium, their metabolism changes, and they partially lose their ability to survive in wine. When wine bacteria are produced by the MBR™ process, this ability is preserved. It was shown that by adding gradually increasing concentration of inhibitory polyphenols to the medium, the wine bacteria in MBR™ form, compared to the same liquid cultures, had a lower mortality rate and better survival, as shown in figure below.

THE UNIQUE FLEXIBILITY AND ROBUSTNESS OF BACTERIA MBR™

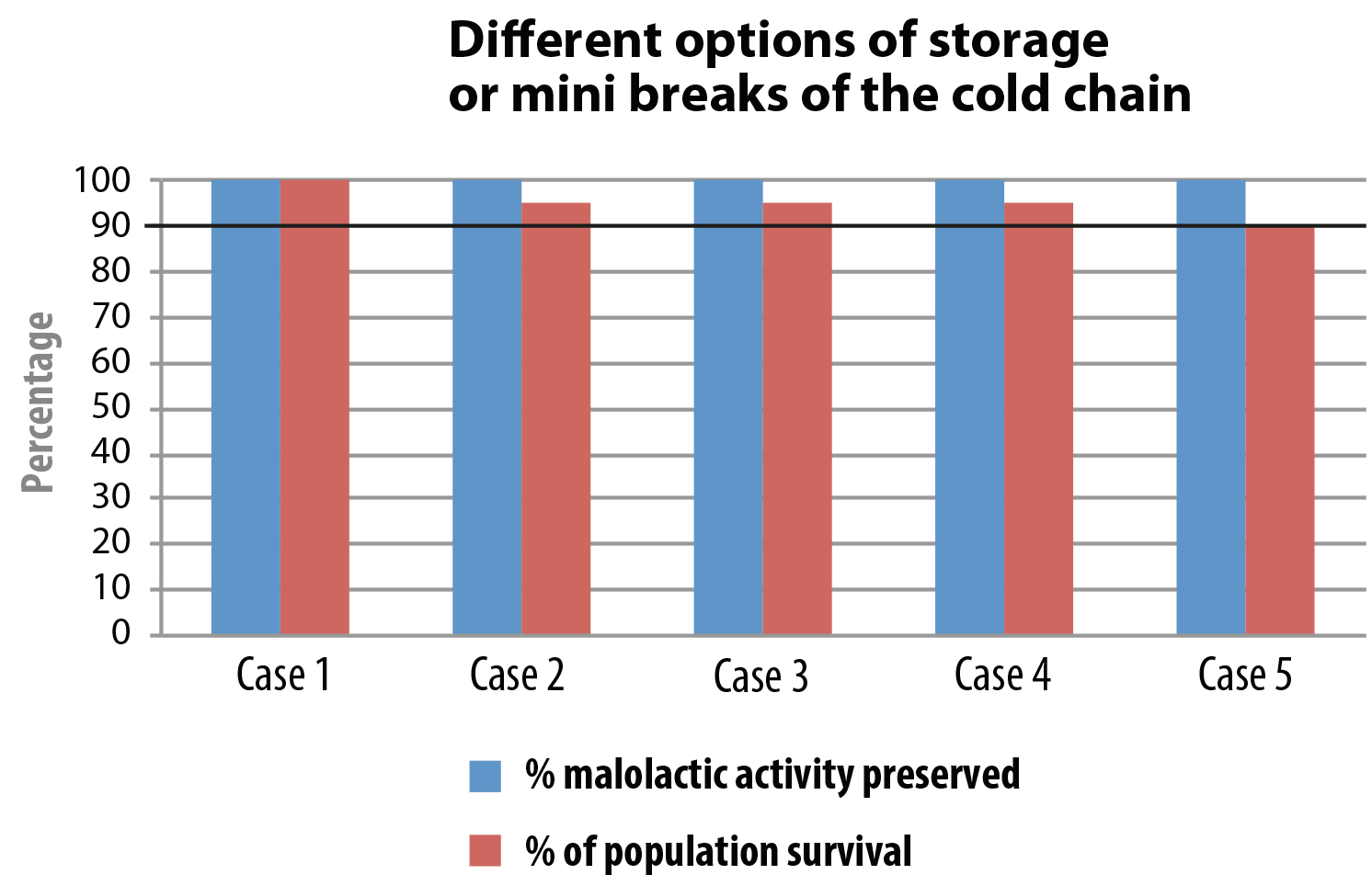

Our wine bacteria MBR™ are easy to use through direct inoculation and without rehydration. They are produced under dry form (obtained by lyophilisation) and due to their high robustness and our strict quality criteria, they do not need to be transported or maintained in complicated cold storage units. They can also tolerate breaks in the cold chain, as long as the temperature does not exceed 25° C for more than 3 weeks, without damaging the efficiency (see figure below) nor the initial shelf life. The survival rate of the wine bacteria is greater than 90% with a guaranteed minimum of 1x1011 cfu/g. The malolactic activity is maintained at 100%.

Moreover, throughout their long shelf life (3 years at -18°C), the wine bacteria MBR™ are known to maintain their efficacy. These unique characteristics are due to MBR™ process and facilitate the work of winemakers.

MBR™ PROCESS AND MALOLACTIC FERMENTATION PERFORMANCE

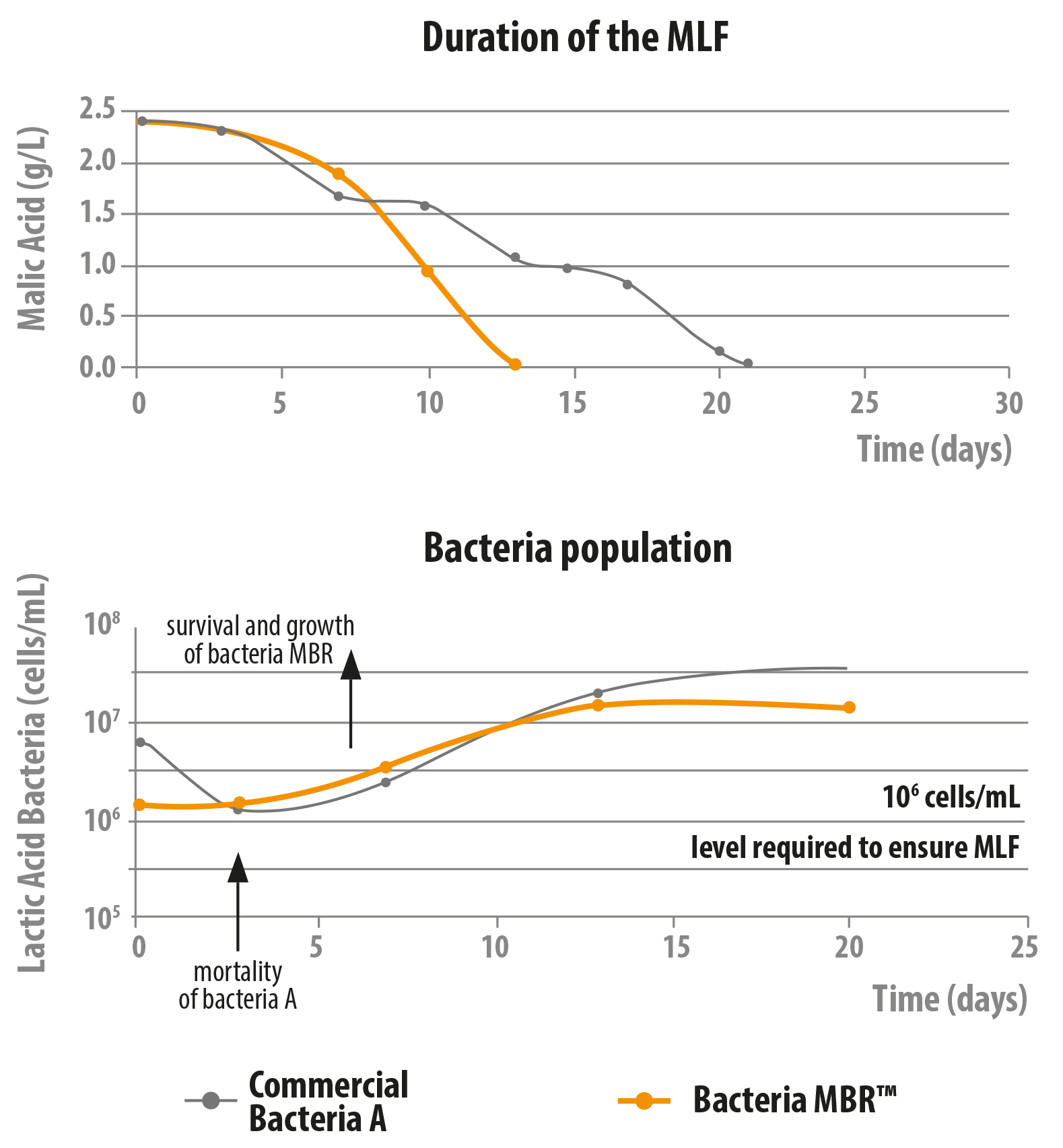

The MBR™ process is synonymous with pre-adaptation of selected wine bacteria to different wines conditions. It assures a strong survival of bacteria and their rapid growth in the must or wines, crucial criteria to achieve a good start and complete MLF after direct inoculation into wine.

The MBR™ process is guaranteed of quality and efficiency because, the quantity of bacteria is not the essential factor to ensure a good MLF performance. For example, despite a high level of population of a commercial bacteria A (ie 107 cells / mL), MLF was carried out in 22 days, whereas with our bacteria MBR™, MLF takes13 days.

For more information on this topic, contact our Lallemand Oenology experts here on Winemak-in or send us a direct message.

You can also go to our Website : www.lallemandwine.com