Restarting stuck malolactic fermentation

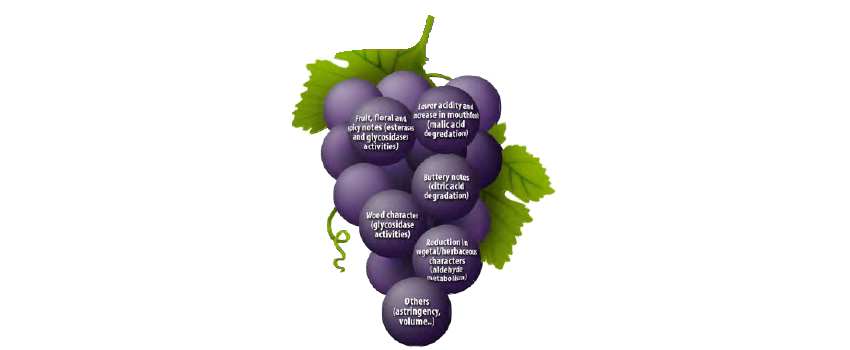

Publiée le 15/04/2018 23:33Lallemand Oenology has developed a fast protocol to restart stuck malolactic fermentation for white, rosé and red wines. With only 3 steps, it is an easy and efficient protocol using a specific cells wells RESKUE to detixify the wine, a suited bacteria nutrient ML REDBOOSt and the efficient selected bacteria LALVIN VP41 MBR .